With Daxium-Air, it’s simpler and less paper.

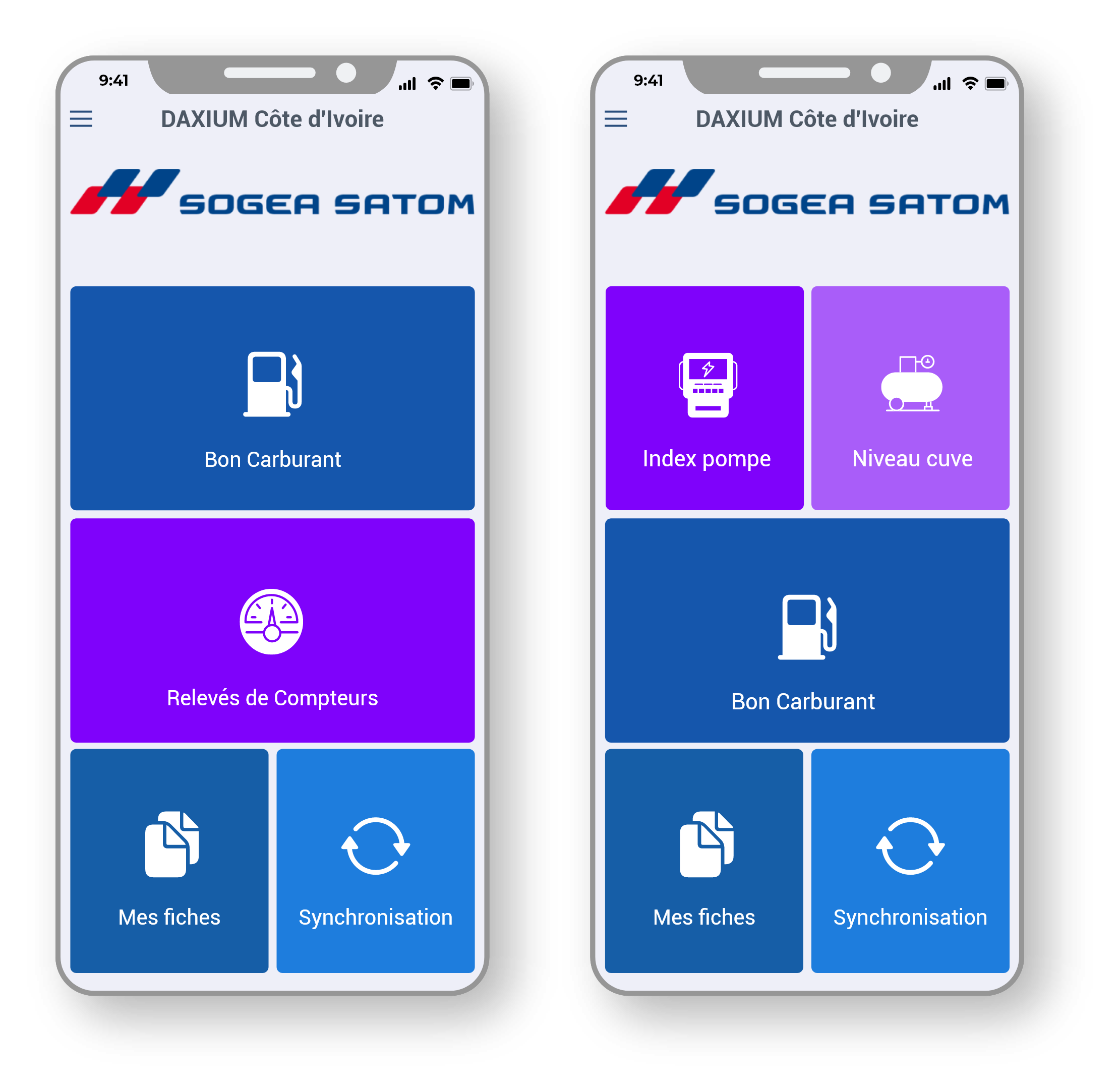

Digitalization is making headway in construction sites. Last year, Sogea-Satom (a subsidiary of Vinci Construction) deployed the Daxium-Air solution in Benin to digitalize gas oil delivery notes, with significant operational benefits, as well as in terms of management and reduction of consumption.

The initiative of the project.

When simplification rhymes with digitalization.

Hence the idea of implementing a solution to digitize delivery notes and consolidate the information chain, with one goal: a single entry, on a tablet/smartphone. The digitization of this operation quickly demonstrates its beneficial effects.

‘A real-time monitoring, control of information reporting, a reduction of paper-based notes. The app is very easy to use, very streamlined, and was well received by the pump operators who only have to enter the gas oil data once. The improvement in processing the notes was all the more critical and expected as they are a primary source of information. By switching from a bi-weekly to daily reporting, it is possible to act quickly and accurately on the management of machines.‘

Reynald Bazille, energy referent at Sogea-Satom.

Since better monitoring means better management, this is reflected in the curve of gas oil consumption, down by 5% since the introduction of the Daxium-Air solution. The implementation of consumption monitoring tools is also among the levers identified by VINCI to reduce the environmental footprint of construction machinery and vehicles and, by extension, contribute to the Group’s goal of reducing GHG emissions by 40% by 2030.

Time savings and fluidity in the flow of information.

‘The implementation of Daxium-Air has resolved the difficulties related to gas oil monitoring that we encountered. We now have reliable and consolidated indicators every day, synchronized with our MATIS equipment monitoring tool. We know the actual daily outputs, the active pumps, the utilization rate of the machines, any overconsumption, etc. If we identify a problem with a machine, we can immediately contact the workshop manager or the fleet manager to act quickly.‘

Angélique Ahouangnivo, Gas Oil Manager at Sogea-Satom Benin, who also recognizes the value brought by the system to her activity.

In the context of the first deployment in Benin, 90,000 delivery notes were digitized, equivalent to avoiding 270kg of paper notes. Since then, the solution has expanded to Côte d’Ivoire, Uganda, Mali, and Niger, and soon to Gabon and Chad. To date, about 150,000 digital delivery notes have been processed, not to mention the numerous virtuous effects generated in operational terms…

Digitalization has its benefits!